Demand-Driven Operations Planning Part 2

When this process began it was one that was driven by production planning and ended when approved by the management team. There was often an embarrassing moment when the demand numbers were presented and they differed from the forecast management plan that had already been presented by the sales and marketing organization and were different from those presented in the planning/production plan. Representatives from both organizations were there and were only able to offer excuses. This had to be the beginning of ridding the process of the silo approach. The sales and marketing forecast in the future, was identified as the demand plan and if any unit would not get produced it was identified as a potential sale, but not able to be produced. This issue when resolved crossed a significant hurdle.

The structure is required to address all opportunities to create and obtain consensus for a comprehensive plan that includes: sales and marketing, new product development, product planning, production, customer service, procurement, and materials planning. These functions, regardless of what they’re called in your organization, need to have input before a plan can be recommended and agreed to for implementation by senior management. Metrics are critical to ensuring buy-in to the process and sign-off by senior management and evaluating how well we’re satisfying our customers. The ones used were:

| Metric | Target | Actual | Change from last month |

| Orders Shipped Complete and On Time (OSCOT) | 100% | 75% | 5% |

| Forecast Accuracy | 85% | 60% | (10%) |

| Finished Goods Inventory Turns | 6 | 4 | 1 |

| In Process Inventory Targets | $ | $ | $ |

| Purchased Parts Availability | 100% | 75% | (25%) |

| Premium Freight Charges | $ | $ | $ |

| Product Delivery Lead-time Reduction | 4 Weeks | 6 Weeks |

Each review began with a metrics discussion with specific next steps defined to reach targets. It was imperative that the measurements were meaningful to senior management.

In this demand driven process we were pointing toward a “One view” consensus forecast demonstrating a realistic view of customer next-period demand that included an analysis and feedback mechanism for forecast error measurement and next-round adjustments.

We also focused on a “One view” consensus supply plan outlining true capabilities and doable contingency plans to meet demand. This ensured that there was a simplified mixing of methodologies layering supply over demand to arrive at the next-period production plan. Then the process built and sustained confidence that appropriate actions would be taken to produce the most accurate plan. This plan would have to take into account all the different forecasts available within the organization, including the statistical forecast, financial plan, customer forecast, geographical forecast, product manager plan, promotional/seasonal forecast and any other plan/forecast that established any expectation in the organization for sales.

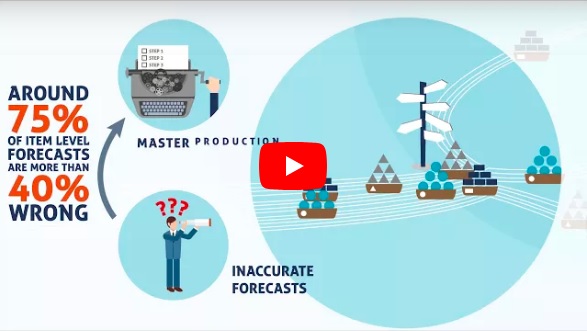

Continuous improvement is critical to the success of any process and since multiple functions are giving forecast input there is a likelihood there will be errors and there could be even compounded errors. Since the forecast will be over multiple periods there may be multiple issues. The secret is, don’t cover up any errors! Recognize it, and get to the root cause and then calculate any impacts. The goal is not perfection, but improvement of incremental accuracy over the previous period. Lessons must be learned and applied.

The process needs to be supported by all levels of the organization. There’s no quicker way to fail to achieve the targets than for any one of the functions to be aware of the possibility that something promised is going to be missed and not say something about it. If there is trust in the organization the plan will be changed in time to react and make appropriate adjustments.

The production and materials planning group in many organizations is the one best equipped to put together a monthly plan. They should be responsible for gathering all the input from all functions, structuring and gaining approval for the plan, and communicating the results. To make this process viable, it’s important to share the demand forecast with all suppliers of the product components. Each supplier must be onboard with the possibility that it will probably be adjusted and lead times can’t be guaranteed. It’s the responsibility of internal and external suppliers to support the plan.

Your path to business success.